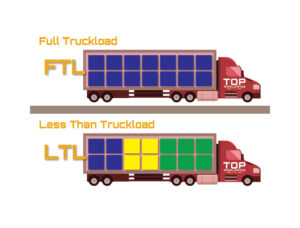

Less-than-truckload (LTL) shipping is a cost-effective way for businesses to move freight that doesn’t require a full trailer. LTL shipments typically weigh between 150 and 15,000 pounds, and with LTL, you only pay for the space your shipment occupies. This approach not only saves money compared to full truckload (FTL) shipping but also reduces environmental impact, since multiple shipments share the same truck.

Despite its advantages, LTL shipping can feel complex. Rates vary based on distance, weight, freight class, and extra services, and shipments pass through multiple handling points, increasing the potential for delays or damage. The good news? Many leading companies have mastered LTL shipping, using smart strategies that reduce costs, improve efficiency, and enhance reliability.

Here’s a closer look at seven game-changing LTL shipping strategies that industry leaders use and how your business can apply them.

1. Know When LTL Makes Sense

LTL shipping isn’t right for every shipment. Understanding when to use LTL versus FTL or parcel shipping is key to optimizing costs and efficiency.

Ideal shipment size

LTL is perfect for shipments that are too large for parcel carriers but don’t require a full truck. Typically, these are shipments of 1–10 pallets or weighing 150–15,000 pounds. Small and medium-sized businesses often rely on LTL because it allows them to ship smaller volumes more frequently without paying for unused trailer space.

Comparing LTL, FTL, and parcel shipping

| Factor | LTL | FTL | Parcel |

| Weight | 150–15,000 lbs | 5,000–45,000 lbs | <150 lbs |

| Capacity | 1–10 pallets | Full trailer (26–52 pallets) | Up to FTL size |

| Transit Time | Longer due to multiple stops | Faster direct delivery | Varies by service |

| Handling | Multiple loading/unloading | Dedicated trailer | Multiple handling steps |

Delivery flexibility and storage benefits

Delivery flexibility and storage benefits

LTL shipping is ideal if you can accommodate delivery windows instead of exact times. It also helps companies with limited warehouse space, allowing smaller, more frequent shipments rather than storing large inventory quantities.

When to choose FTL instead

- High-value or fragile items that require minimal handling

- Shipments over 15,000 pounds or those needing expedited delivery

By analyzing your typical shipments and business needs, you can match the right shipping method to every order and avoid unnecessary costs.

2. Master the LTL Shipping Process

Top companies excel at LTL because they understand every step of the process—from quoting to final delivery. Knowing the process reduces delays, prevents unexpected fees, and keeps shipments secure.

Requesting quotes and booking

Unlike FTL, LTL carriers often rely on predetermined rate matrices called tariffs. Rates are based on weight, class, volume, and shipping routes. To get accurate pricing:

- Provide full shipment details: pallet weight, dimensions, origin/destination, and pickup/delivery times

- Classify freight correctly: NMFC classification codes must match your shipment type and handling needs

- Include all accessorial requirements: liftgate, residential, or inside delivery services

- Use digital portals: Many 3PLs and carriers offer online quoting tools to compare multiple providers quickly

Packaging and labeling best practices

Proper packaging and labeling protect shipments during multiple handling points.

Packaging tips:

- Use strong wood pallets capable of holding double-tiered loads

- Stack boxes squarely with no overhang

- Wrap loads from bottom to top with 50% overlap between layers

- Crate fragile items with proper internal blocking

Labeling tips:

- Match labels to the Bill of Lading

- Place labels on the sides of packages, not just the top or bottom

- Use multiple labels on large pallets for visibility

- Highlight handling instructions with bright-colored labels (“Fragile,” “Do Not Stack”)

Pickup, transit, and delivery

LTL shipments often pass through several trucks and hubs:

- Local pickup with nearby shipments

- Arrival at a central terminal for sorting

- Long-haul linehaul to another terminal

- Processing at the destination terminal

- Final delivery via a truck with appropriate accessorial services

Average LTL delivery times range from 2–5 days depending on distance and route. Proper preparation ensures smooth handling and avoids costly delays.

3. Leverage Data to Improve LTL Performance

Top-performing companies use data to optimize LTL shipping. Tracking key metrics helps identify cost-saving opportunities and improve service.

Key metrics to track

- Cost per pound: Standardize expenses across shipment sizes. For example, a 1,440-pound shipment costing $507.34 equals $0.35 per pound.

- On-time delivery rates: Aim for 90% or higher. Real-time tracking tools narrow delivery windows and improve customer satisfaction.

- Damage rates: LTL shipments have higher risk due to multiple handling points. Track all damage cases, not just claims, and calculate damage-free shipment percentages.

Carrier performance KPIs

Compare carriers based on:

- Billing accuracy (95%+ target)

- Accessorial charges

- Tender acceptance rates

Using KPIs to evaluate and share performance data with carriers often results in improved service without extra cost.

4. Build Strategic Partnerships

Working with 3PLs, preferred carriers, and freight marketplaces can significantly reduce LTL costs.

Why 3PLs help

Third-party logistics providers combine shipments from multiple clients to secure volume-based discounts. They also pre-qualify carriers and provide tracking tools, saving time and effort. Companies often save 8–13% on LTL costs in their first year with a 3PL.

Carrier negotiations

Negotiations should cover:

- Volume commitments

- Service level agreements (SLAs)

- Accessorial charges

Long-term relationships with carriers can yield better rates and priority service.

Freight marketplaces

Online platforms like Schneider FreightPower, Freightera, and uShip let you instantly quote, book, and track shipments while comparing multiple providers. These tools give shippers the ability to make cost-effective, informed decisions.

5. Embrace Intermodal and Eco-Friendly Options

Sustainability and efficiency go hand in hand. LTL shipping naturally reduces fuel use, but companies can go further by combining truck and rail for long hauls.

Intermodal shipping

- Trucks handle first- and last-mile delivery

- Trains carry freight long distances, consolidating multiple shipments efficiently

- Reduces traffic, emissions, and often cost

Shared loads

- Multiple shippers sharing the same trailer reduces fuel consumption

- Trains emit 75% less greenhouse gas than trucks

- Eco-conscious customers are increasingly willing to pay more for sustainable shipping

Sustainable packaging

- Use recyclable or reusable materials

- Optimize space in containers

- Fit packaging to products to minimize waste

Environmentally friendly practices appeal to consumers while strengthening your brand image.

6. Optimize Packaging and Sustainability

Packaging affects costs, safety, and environmental impact.

Best practices:

- Choose pallets and crates designed for durability

- Avoid overhang and uneven stacking

- Wrap securely with stretch film

- Use eco-friendly materials whenever possible

Sustainable packaging not only protects your freight but can also improve brand perception and sales.

7. Continuously Review and Improve

LTL shipping is not static. Top companies regularly review metrics, update processes, and stay informed on industry trends. Continuous improvement ensures:

- Lower costs

- Reliable deliveries

- Fewer damages

- Higher customer satisfaction

Combining all seven strategies creates a comprehensive approach that turns LTL from a simple expense into a strategic advantage.

Take Your LTL Shipping to the Next Level

Smart LTL shipping saves money, improves reliability, and enhances customer satisfaction. By understanding your shipments, mastering the process, leveraging data, building partnerships, embracing sustainability, and continuously improving, you can turn LTL into a competitive edge.

Ready to optimize your LTL shipping? Partner with TOP Worldwide today and start shipping smarter, faster, and more efficiently.

Jeff Berlin

Jeff Berlin

is the Chief Operating Officer of E.L. Hollingsworth & Co. and serves as the Senior Operations Executive for TOP Worldwide and Native American Logistics. With over 30 years of experience leading logistics and trucking companies, he brings deep industry expertise to his role. Jeff is also a CDL-A driver and a private pilot. Contact Jeff at jberlin@elhc.net.